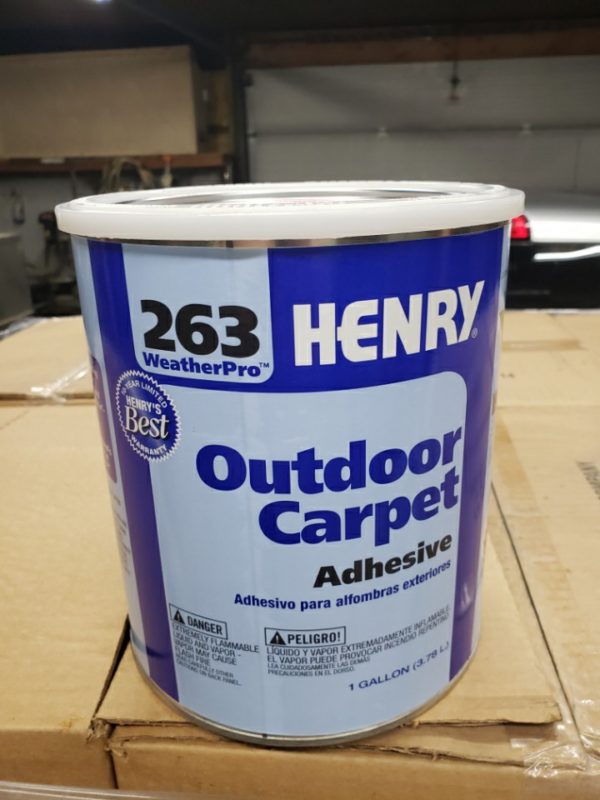

Large quantities of toxic gases can also be released which, if the fire occurs in an underground facility, represents a particular threat to life. However, one drawback is that lightweight materials can be easy to ignite and can have poorer fire resistance than heavier products. Rapid developments in lightweight materials make it possible to build ships, high-speed trains, metro trains, buses and other vehicles with improved fuel economy and able to carry more load per litre of fuel, and thus with reduced environmental impact. Using both products for the best way they perform.Fires in transport systems Fires in transport systems are a challenge for fire experts. Then I use contact cement for the edge wrap. I will use Henry's 263 on the surface then lay the carpet roll and let dry for at least 24 hours. I made the descision out of ease of use and quick adhesion. So my final decision on adhesive is to use both Henry's 263 and Contact cement. This is what Roberts looked like after just 3 hours soaking in water Henry's 263 after soaking in water for 14 hours I only let the Henry's 263 dry about 18 hours then soaked it in water for 14 about hours and it is the same as when it was dry! It repels water and is truly waterproof! Adhesion is great! Roberts and Henry's 663 absorbed water like a sponge after just 3 hours. Just for the hell of it I ran another quick test and it performed awesome! HENRY 263 WeatherPro Outdoor Carpet Adhesive bonds outdoor carpet and artificial turf to concrete, asphalt paving, abraded fiberglass substrates, roughened aluminum boat decks, and exterior- or marine-grade plywood deckingSo it's made for what we are doing here! Dry strength was just as good as Roberts 6700 and would have destroyed the carpet and left the backing behind if I tried to remove it.Īgain I soaked this piece for about 3 hours to simulate fishing in the rain all day.Īfter 3 hours soaking, the Dap contact cement is showing the same strength as when it was dry and the carpet backing is staying firmly attached to the plywood coated with Helmsman. I have worked with it many times doing laminate. Definitely no repositioning, but I knew that already. Which also claims only to be water resistant.Īfter coating both sides and letting them set up, adhesion was instant. Then I decided to try Dap Contact Cement Original. And the piece I peeled up re-glued itself down and the strength seemed to be just as strong as before. One good thing is after letting it dry again the glue returned to the size and strength it was before. It had slight resistance, but nothing like the dry test. The Roberts 6700 soaked up water like a sponge.Īnd the strength was compromised. The other half I soaked in water for about 3 hours to simulate fishing in the rain all day. The adhesive worked very well dry and I destroyed the carpet trying to pull it up and the backing stayed glued All test pieces were coated with 3 coats of Helmsman Spar Urethane letting each coat dry at least 8 hours and no sanding in between coats.įirst test was with Roberts 6700 Outdoor Carpet Adhesive.

Holds to the wood well and glue sticks to it well. I haven't found the Helmsman Spar Urethane to be a problem at all. looks like I'm gonna go with Contact Cement.

0 kommentar(er)

0 kommentar(er)